Flexible Packaging Testing Services That Offer A Competitive Advantage | ASTM, ISO, OTR, MVTR and Much More

The Need For Comprehensive, Unbiased 3rd Party Flexible Packaging Testing

For nearly 30 years, Flex-Pack Engineering has been providing unbiased, 3rd party ASTM and ISO flexible packaging testing. We identified a need with our customers to analyze and validate the effectiveness and usefulness of their products in the marketplace, or to help them understand the requirements for entering a new market. For example, a customer may only sell into the potato chip industry but would like to start selling into the frozen chicken or meatball industry. Flex-Pack helps our customers understand the requirements for this new market and provide the testing services to meet the fitness for use and chain of use requirements.

Perhaps the most important element that Flex-Pack offers our customers is the ability to interpret test results and help them solve their flexible packaging problems. A normal testing lab will deliver testing results but not provide any insights into what the results mean in the context of your problem. In short, it is not the testing that is so important, it is the answers and recommendations to solve the problem and improve your flexible packaging products.

Additionally, many manufacturing facilities such as film producers, converters, printers, laminators, bag, and packaging converters may not have a packaging engineer and/or full laboratory, or the time for flexible packaging testing. Also, they may need to do testing that is outside the scope of their in-house capabilities.

Furthermore, some customers may have a good flexible packaging product that they want to make even better to help them compete in the marketplace. Flex-Pack Engineering can offer reverse engineering services including competitive analysis as well as defect analysis and production troubleshooting to help our customers understand why their competitors packaging products outperform their own and make recommendations on how to improve their flexible packaging product.

Flex-Pack Engineering is able to provide these comprehensive services and help customers gain a competitive advantage in the marketplace.

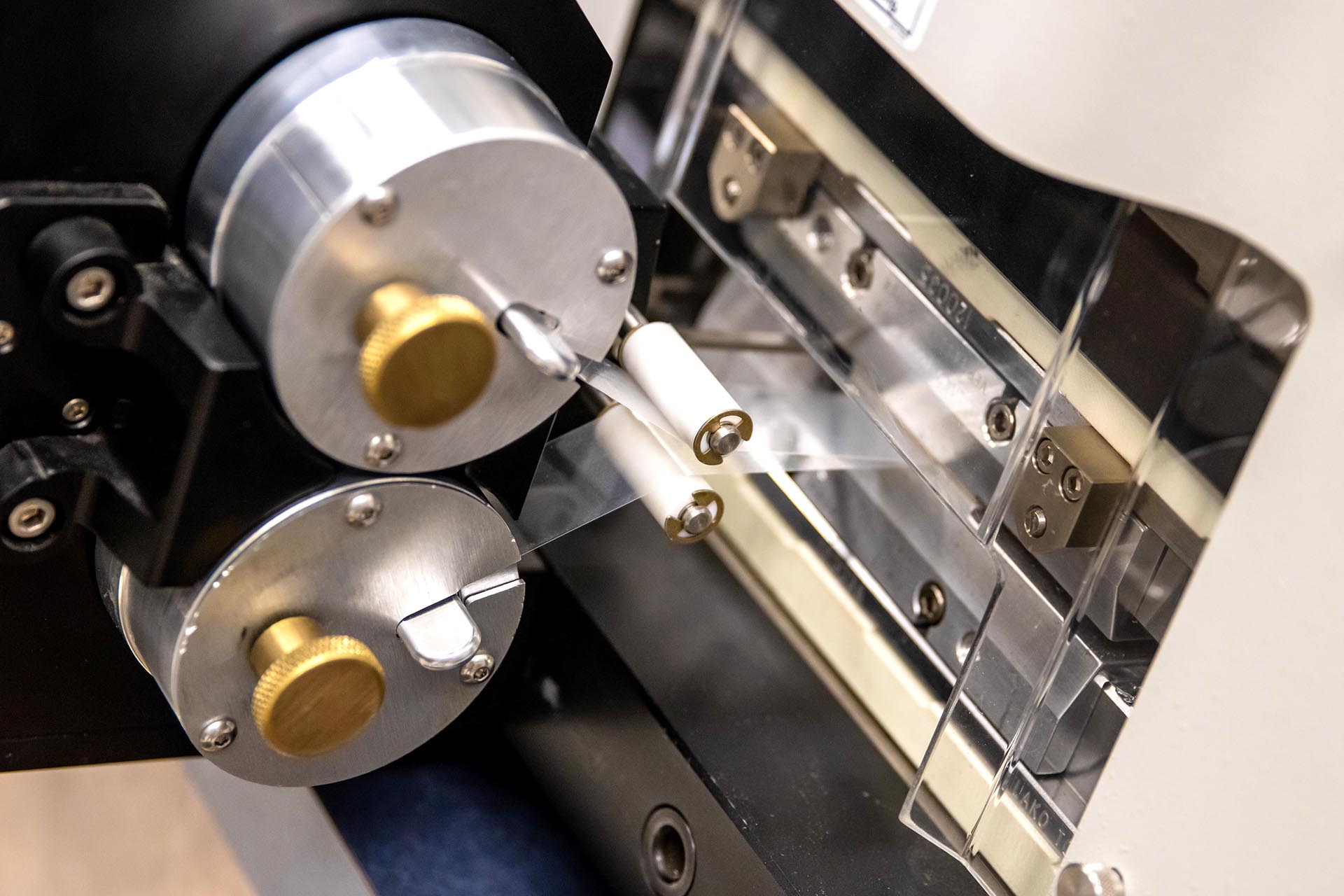

Analytical and Physical Flexible Packaging Testing Services We Provide

At Flex-Pack Engineering we offer a wide array of flexible packaging testing services to meet our customer’s needs. Whether it is one test or one hundred we have the capabilities to handle your requirements. We can also design and perform custom flexible packaging tests as needed.

Analytical Services:

Ash, DSC Testing (Differential Scanning Calorimeter), TGA (Thermo Gravimetric Analysis), TMA (Thermo Mechanical Analysis), DMA (Dynamic Mechanical Analysis), FTIR Transmission and ATR, Microscope (Fourier Transform Infrared), Solvent Extraction, GCMS (Gas Chromatography Mass Spectrometry), HPLC (High Pressure Liquid Chromatography), XRF (X-Ray Florescence), ICPMS (Inductively Coupled Plasma Mass Spectrometry Inductive Coupled Plasma), AA (Atomic Absorption), SEM (Scanning Electron Microscopy), OIT (Oxidative Induction Time), UV-VIS Spectrophotometry, Karl Fisher Titration, Moisture Analysis, and more.

Physical Testing Services:

OTR (Oxygen Transmission Rate) , MVTR (Moisture Vapor Transmission Rate) , Tensile, Elongation, Secant Modulus, COF (Coefficient of Friction), Block Re-Block, Elmendorf Tear, Dart Drop, Slow Rate Puncture, Puncture Protrusion (puncture resistance), Thickness Profile, Burst Testing, Melt Index, Density, Optical Microscopy, X-Section Analysis, Surface Analysis, Heat Seal, Heat Seal Profile, Hot Tack, Hot Tack Profile, Ink Draw Down, Ink Rub, Sheffield Smoothness, Gurley Stiffness, Gelbo Flex, Surface Tension Testing (Dyne Testing), Haze, 45 degree Gloss, 60 degree Gloss, Opacity, Lab Color Testing, Capillary Rheometry (Rheology) and more.

Flex-Pack Engineering: Your Best Choice For Flexible Packaging Testing Services

What separates Flex-Pack Engineering is our extensive know-how in testing flexible packaging based on our nearly 30 year education in developing packaging products. We know how to do the tests correctly and correlate the results to the customer’s problem or what the rules are in making a specific package.

We have experience in all facets of flexible packaging including:

- Blown film

- Cast film

- Extrusion lamination

- Adhesive lamination

- Printing

- Metalizing

- Bag making

- Secondary processes

- Compounding of additives

- Resin chemistries

- Additive chemistries

- Combining additive chemistries and resin chemistries to achieve something special

We have done all of the above services for many years professionally which allows us to review a package and know what we are looking at immediately and when a customer describes the problem, we have a good idea of the cause of the problem and direction of the solution. We cannot say it often enough to our customers: it is not the testing that is so important, it is the answers and recommendations to solve the problem and improve your flexible packaging products.

Flex-Pack Engineering is here to help you find the answers you need to be more competitive and improve your products in the marketplace. Ready to start a conversation? Give us a call at 888-300-1492 or contact us today!