Reverse Engineering for Flexible Packaging Products

At Flex-Pack Engineering we understand the importance of reverse engineering in the flexible packaging industry. When we have a reverse engineering project the starting point is always with Optical Microscopy (Scope), Fourier Transform Infrared (FTIR) and Differential Scanning Calorimetry (DSC).

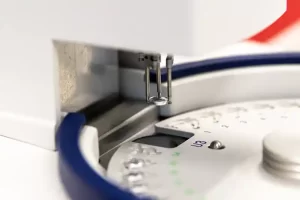

In the microscope cross-section we take the film and look for the number of layers present and measure the thickness of each layer. The cross-section will also help us determine if it is a lamination with adhesive or if it is a co-extrusion, because those layer interfaces look different under magnification. Once we have this data we can infer, based on our experience, what most likely is the film structure. For example, a 7 layer structure will usually have the barrier layers located in the center layers.

Once we have this initial understanding of the film, we run multiple FTIR scans to provide a thorough chemical fingerprint. We scan the outside layer, the inside layer and then run a transmission scan that goes all the way through the layers, to pick up anything that is on the inside of the film. From these analyses we can determine the family of polymers and additives that are present in the film. If necessary, we can use additional techniques such as FTIR microscope to further analyze the structure, layer by layer to gain more detailed information.

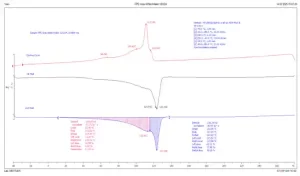

Now that we understand the structure of the layers as well as the chemical composition of the material, we then employ DSC to produce a thermal fingerprint of the film. This thermal analysis fingerprint is used to look at the specific melt points of the polymers to further identify what specific polymers and additives are present.

By using the Microscope Cross-Section, FTIR Chemical Fingerprint, and DSC Thermal Analysis we can see what is present physically, chemically, and thermally, and based on our experience we can pretty well determine what is the overall structure and what materials were used in its construction

Why Flex-Pack Engineering for Reverse Engineering Services?

Flex-Pack Engineering is your ideal partner for reverse engineering services in the flexible packaging industry. We bring our long history (over 30 years of experience) to packaging analysis and evaluation. We not only provide you with results, but we also provide insights and recommendations on what the results mean and how to improve or upgrade your current capabilities to be able to participate in additional industries and market segments.

Let’s have a conversation! Contact us today at 330-704-9436 or fill out our request information form and learn how Flex-Pack Engineering can help with your reverse engineering initiatives!