DSC Thermal Analysis & Testing

Differential scanning calorimetry (DSC) is a thermo-analytical technique in which the difference in the amount of energy required to increase the temperature of a sample and reference is measured as a function of time. Both the sample and reference are maintained at nearly the same temperature throughout the experiment. Generally, the temperature program for DSC thermal analysis is designed such that the sample holder temperature increases linearly as a function of time. The reference sample should have a well-defined heat capacity over the range of temperatures to be scanned.

In the engineered flexible packaging industry, DSC thermal analysis measures the crystalline content of a polymer or material. Materials that have crystalline content will have a phase change from solid to liquid or liquid to gas. This fully relaxed annealed melting point of a material is a unique property that is reproduceable and can be used for referencing.

The observed thermal transitions can be utilized to compare materials, although the transitions alone do not uniquely identify composition. The composition of unknown materials may be completed using complementary techniques such as FTIR spectroscopy.

DSC is a versatile technique that can be used to study a wide variety of materials and how they relate to specific processes. It is also a powerful tool for the characterization of materials and the study of chemical reactions.

Applications of DSC Thermal Analysis

DSC thermal analysis is used in a wide variety of applications, including:

- The characterization of polymers: DSC can be used to determine the glass transition temperature (Tg), crystallization temperature (Tc), and melting temperature (Tm) of polymers. These properties can be used to compare different polymers and to understand the behavior of polymers under different conditions.

- The study of chemical reactions: DSC can be used to study the kinetics of chemical reactions. The rate of a reaction can be determined from the slope of the heat flow curve.

- The quality control of materials: DSC can be used to determine the purity of materials and to identify contaminants.

Advantages of DSC Thermal Analysis

DSC thermal analysis is a versatile and powerful technique that has many advantages over other thermal analysis techniques. Some of the advantages of DSC include:

- It is a direct measurement of heat flow. This means that it is not affected by changes in the sample’s heat capacity.

- It can be used to study a wide variety of materials and how they relate to processes.

- It is a sensitive technique that can be used to detect small changes in the sample.

- It is a rapid technique that can be used to obtain results in a short period of time.

How Flex-Pack Engineering Utilizes DSC Thermal Analysis

Here at Flex-Pack Engineering we use DSC testing as a thermal analysis tool in conjunction with FTIR to look at the chemical composition of different polymeric materials. We use DSC testing as part of our analysis and evaluation process for the following:

- To help solve a customer’s flexible packaging problem.

- Competitive analysis, to help determine what makes a competitor’s package work so well.

- Provide reverse engineering of flexible packaging products.

- Product and process development of flexible packaging products

DSC Testing is a very useful tool in the analysis of flexible packaging materials.

Flex-Pack Engineering Provides Fast and Reliable DSC Thermal Analysis

At Flex-Pack Engineering we bring over 30 years of experience in our flexible packaging analysis and evaluation, and DSC thermal analysis is an important tool that we use in our workflow. We know how to use DSC testing to get the information our customers need to improve their packaging products.

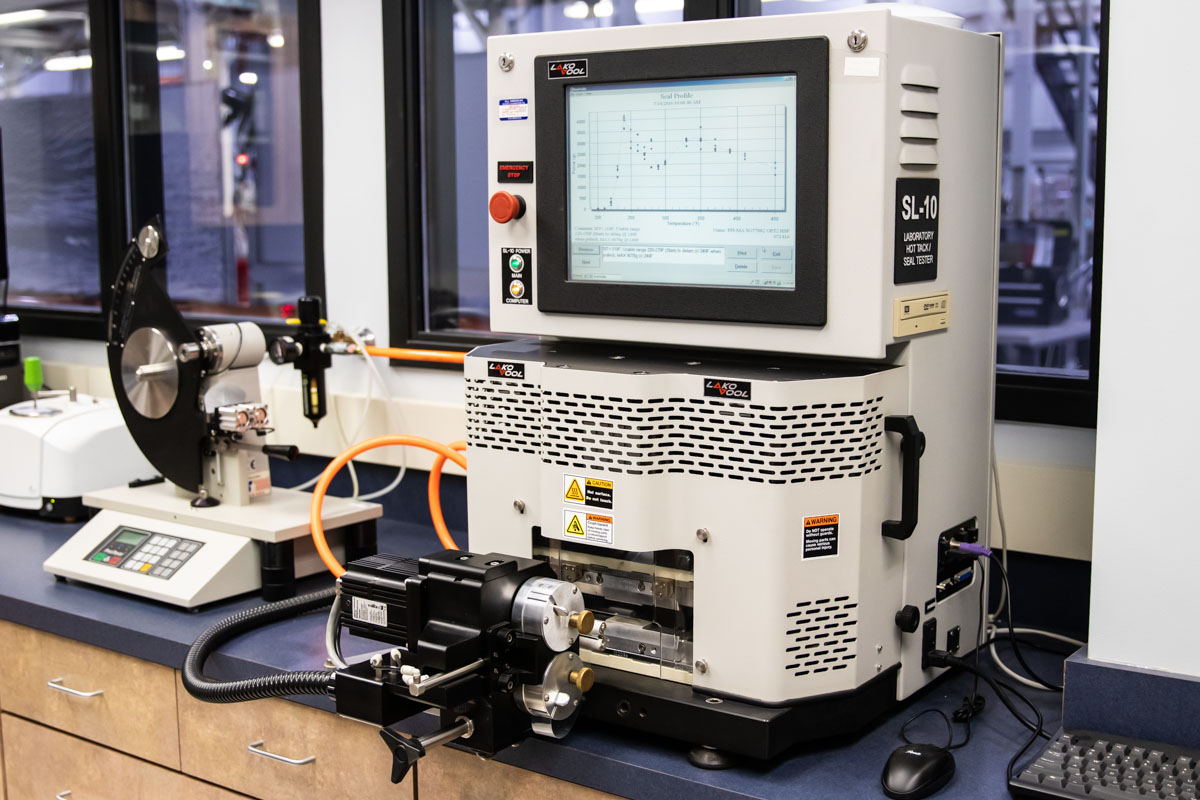

Furthermore, we have invested in state-of-the-art DSC thermal analysis and testing equipment to provide reliable results with better than industry standard turnaround times. All our DSC testing equipment is calibrated to NIST traceable standards and verified to be working properly before testing begins.

While having the knowledge and equipment necessary to provide DSC thermal analysis is important, what benefits our customers the most is Flex-Pack’s extensive background and experience in flexible packaging product and process development. We not only provide you test results, but critical insights and recommendations on how to improve your packaging design, or production line operations. We offer very competitive pricing with exceptional turnaround time and friendly customer service to help you with all your flexible packaging requirements.

Let’s have a conversation! Contact us today at 330-704-9436 or fill out our request information form and learn how Flex-Pack Engineering can help with your DSC thermal analysis requirements today!